Holloway Houston provides complete inspection and repair services to maintain your lifting equipment at peak safety and performance levels. Our experienced team conducts thorough inspections across a broad range of equipment, from chains and slings to plate clamps, master links, lifting points, and load cells. By identifying potential issues early on, we help minimize costly downtime and avoid safety risks.

We focus on maintaining your lifting equipment in optimal condition through visual inspections and detailed repairs. Our skilled technicians are equipped to handle everything from routine checks to complex repairs, keeping your equipment running smoothly and compliant with safety regulations.

Alongside inspections, we also specialize in modernizing outdated lifting gear to meet current industry standards. By upgrading your systems, we improve safety and performance, helping your equipment operate at peak efficiency.

Key Services

- Hoist and Crane Inspections: Our technicians perform thorough inspections of hoists and cranes, following ASME B30, API, and OSHA standards. Each inspection includes visual checks and operational tests to maintain safety and compliance. Monthly checks of wire ropes and hooks help keep your equipment in reliable condition.

- Slings and Loose Lifting Gear Inspections: We inspect slings, shackles, hooks, and other lifting gear to confirm they meet safety standards. With portable proof testing equipment, we can test your gear on-site, helping you avoid downtime.

- Lifting Devices Inspection: Our team examines below-the-hook lifting devices like material and personnel baskets. Following ASME B30.20 standards, we inspect, test, and assess for service needs to keep your lifting devices safe and ready for use.

- Lifting Magnet Inspections: Annual breakaway tests for lifting magnets verify they are up to ASME B20.20 standards. These tests support safe magnet use, helping to prevent issues during operation.

- Plate Clamp Repair: Our plate clamp repairs include full disassembly and detailed inspections. We replace worn parts like cams, pins, jaws, pads, and shackles, then conduct proof tests to meet ASME B30.20 standards

- Hoist Repair Services: We repair various hoist types, including lever chain, hand chain, electric, air hoists, and trolleys. Our technicians inspect load chains, hooks, latches, bearings, pawls, and gears to keep your hoists working smoothly.

Repair & Recertification

Our repair and recertification services are designed to extend the life of your lifting equipment and meet all regulatory standards. We offer:

- Chain and Sling Repairs: We repair and refurbish chains and slings, bringing them to optimal condition for safe lifting operations. Our recertification process includes thorough inspections and testing to verify their load-bearing capabilities.

- Hoist and Load Cell Repairs: Our technicians are skilled in repairing a variety of hoists and load cells, restoring them to peak performance. Each repaired unit undergoes stringent testing to meet operational standards.

- Welding and Fabrication: We provide expert welding and fabrication services, utilizing certified welders to perform repairs and modifications. Our services maintain structural integrity and compliance with industry standards.

- In-House Machining: Our in-house machining capabilities allow us to fabricate custom parts and components, so your equipment operates seamlessly. This service includes precise machining and finishing to meet specific requirements.

Proof Testing

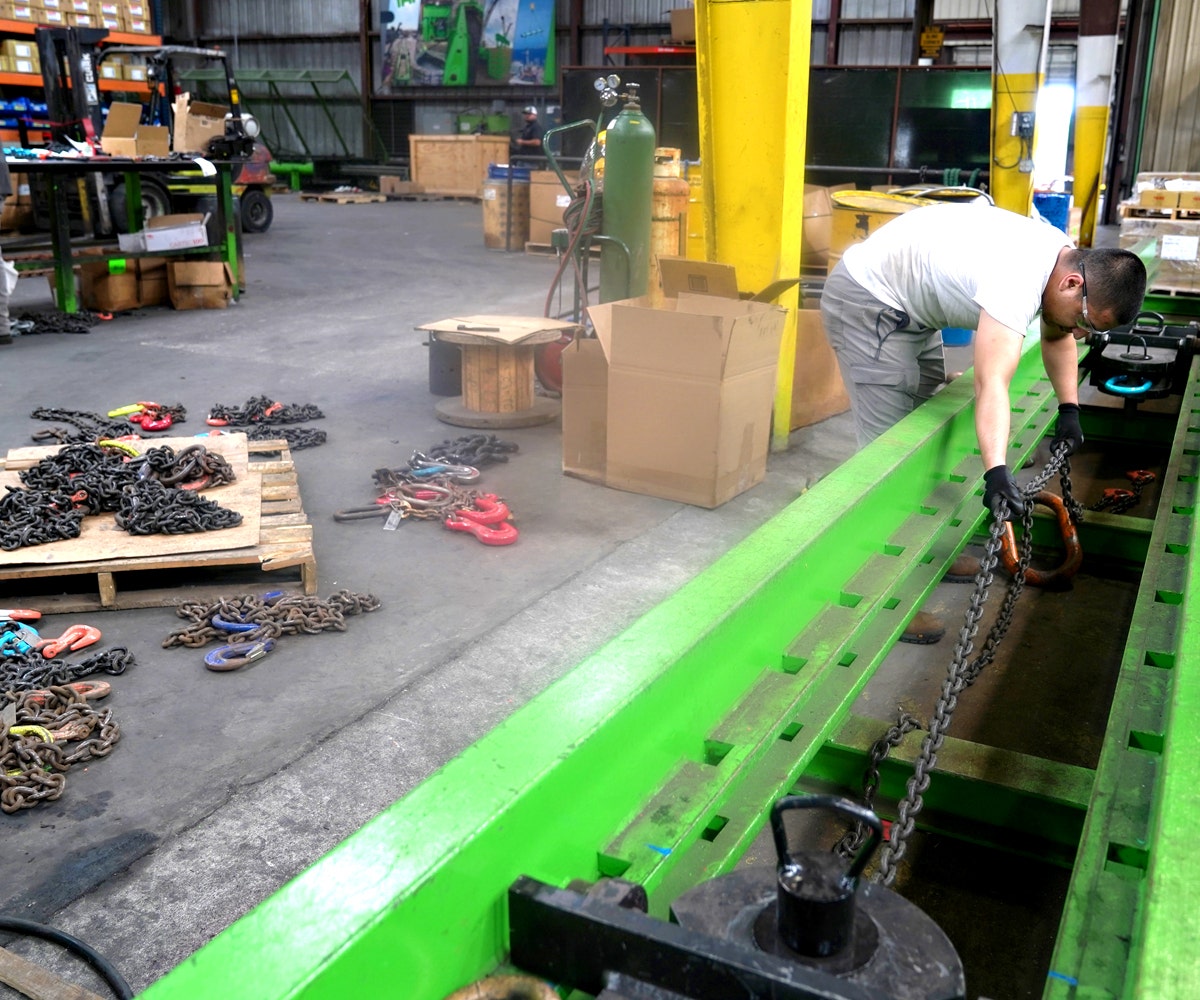

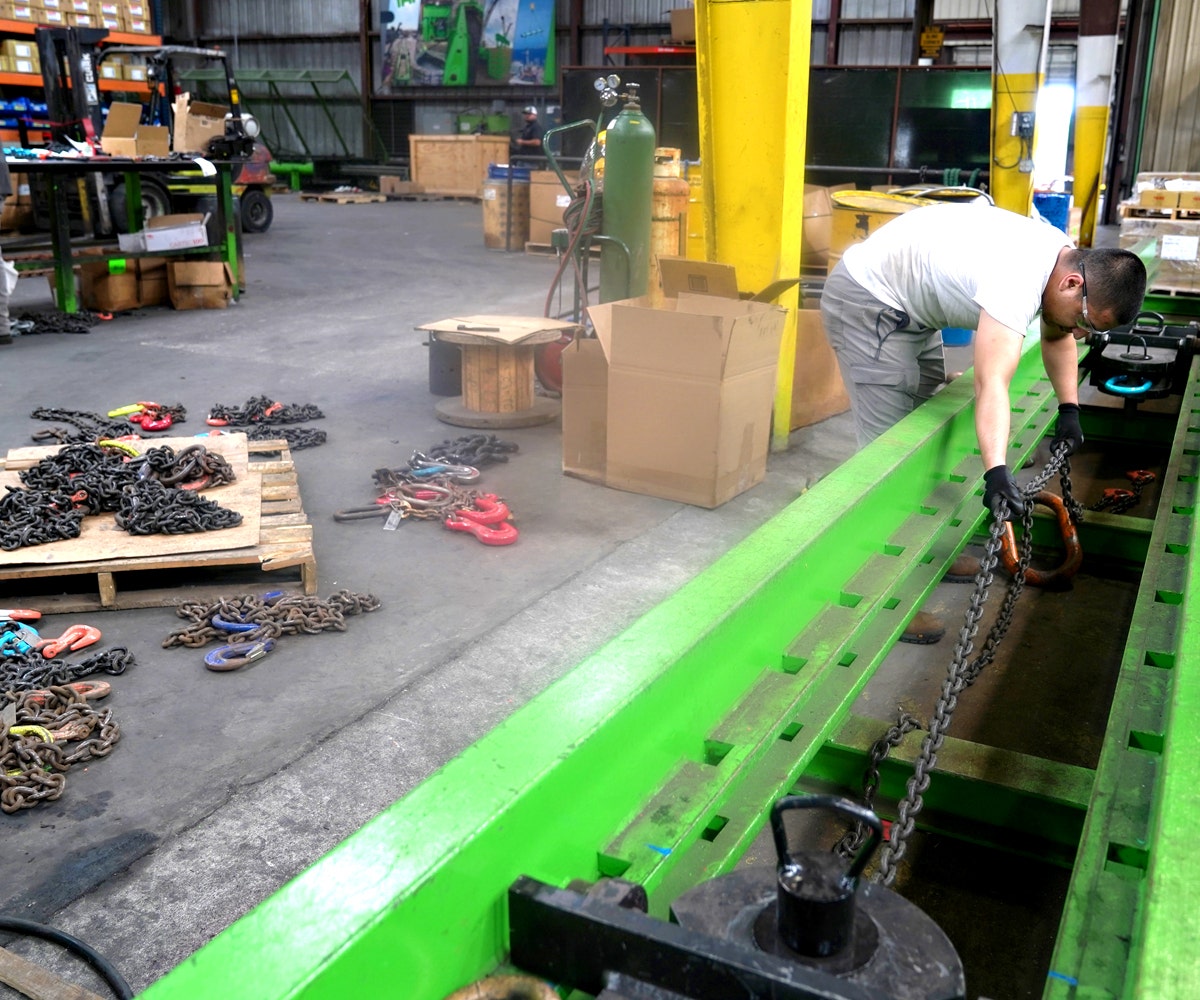

Proof testing is a critical component of our services at Holloway Houston. This process involves subjecting lifting equipment to loads that exceed their normal operational limits to verify their structural integrity and safety. Our proof testing services include a wide range of equipment, from chains and slings to hoists and load cells. By applying loads that simulate real-world conditions, we can confirm that your equipment can handle the stresses and strains of regular use. Our advanced testing facilities are equipped to handle various types and capacities, providing you with the assurance that your equipment is both safe and reliable. Proof testing not only helps prevent accidents but also extends the lifespan of your equipment by identifying potential issues before they become critical failures.

Rigging Equipment Inspection

Regular inspection of rigging equipment is essential to maintain safety and efficiency in lifting operations. Our team conducts comprehensive inspections of rigging gear, including shackles, blocks, elevator links, and spreader bars. These inspections identify wear and tear, corrosion, and any other signs of damage that could compromise the equipment's performance. Through detailed visual and non-destructive testing, we confirm that all rigging equipment meets the required safety standards. Our rigorous inspection protocols help prevent accidents and downtime, allowing your lifting operations to run smoothly and safely.

Load Testing Equipment

Load testing is a crucial service that verifies your lifting equipment can handle the maximum loads specified for its use.Our load testing services involve applying controlled loads to equipment such as cranes, hoists, and load cells, verifying their capacity and performance. This testing helps identify any weaknesses or defects that could lead to failure during actual operations. By performing load tests, we provide assurance that your equipment is capable of safely lifting and moving the required loads, thereby enhancing overall safety and reliability in your operations.

Importance of Inspecting and Repairing Lifting Equipment

Lifting equipment is subject to wear and tear over time, and it is important to inspect it regularly to identify any potential problems. This can help to prevent accidents and injuries, and it can also extend the life of your equipment. Regular inspections are essential to identify potential problems early on and prevent costly downtime. Our inspection services help make certain your equipment operates safely and reliably.

Why Regular Inspections Matter

Lifting equipment is critical to many operations, and its failure can lead to serious accidents. Regular inspections are essential to identify potential problems early on and prevent costly downtime. Our inspection services help make your equipment operate safely and reliably. By conducting regular inspections, we can identify wear and tear, corrosion, and other signs of damage that could compromise your equipment's performance. This proactive approach not only enhances safety but also extends the lifespan of your equipment, allowing it to operate efficiently.

Additional Services

In addition to inspection repair services, we offer various lifting slings, including wire rope, synthetic, and chain slings. Our extensive inventory of rigging hardware, such as shackles, hooks, and turnbuckles, provides the right tools for every job. Browse our selection of spreader bars for safe and efficient load distribution.