Bolt Type Shackles

- Green Pin G-4163 Standard Bolt Type Bow Shackle BN - 3/8" - GPGHMB10was $19.64 Special Price $17.97

- Green Pin G-4163 Standard Bolt Type Bow Shackle BN - 1/2" - GPGHMB13was $26.73 Special Price $24.46

- Green Pin G-4163 Standard Bolt Type Bow Shackle BN - 5/8" - GPGHMB16was $32.12 Special Price $29.39

- Green Pin G-4163 Standard Bolt Type Bow Shackle BN - 3/4" - GPGHMB19was $41.86 Special Price $38.30

- Green Pin G-4163 Standard Bolt Type Bow Shackle BN - 7/8" - GPGHMB22was $55.79 Special Price $51.05

- Green Pin G-4163 Standard Bolt Type Bow Shackle BN - 1" - GPGHMB25was $79.83 Special Price $73.04

- Green Pin G-4163 Standard Bolt Type Bow Shackle BN - 1-1/8" - GPGHMB28was $117.27 Special Price $107.30

- Green Pin G-4163 Standard Bolt Type Bow Shackle BN - 1-1/4" - GPGHMB32was $142.91 Special Price $130.76

- Green Pin G-4163 Standard Bolt Type Bow Shackle BN - 1-3/8" - GPGHMB35was $184.40 Special Price $168.73

- Green Pin G-4163 Standard Bolt Type Bow Shackle BN - 1-1/2" - GPGHMB38was $248.87 Special Price $227.72

- Green Pin G-4163 Standard Bolt Type Bow Shackle BN - 1-3/4" - GPGHMB45was $372.36 Special Price $340.71

- Green Pin G-4163 Standard Bolt Type Bow Shackle BN - 2" - GPGHMB50was $483.53 Special Price $442.43

- Green Pin G-4163 Standard Bolt Type Bow Shackle BN - 2-1/4" - GPGHMB57was $1,060.00 Special Price $969.90

- Green Pin G-4163 Standard Bolt Type Bow Shackle BN - 2-1/2" - GPGHMB65was $1,262.42 Special Price $1,155.11

- Green Pin G-4163 Standard Bolt Type Bow Shackle BN - 3" - GPGHMB75was $1,604.55 Special Price $1,468.16

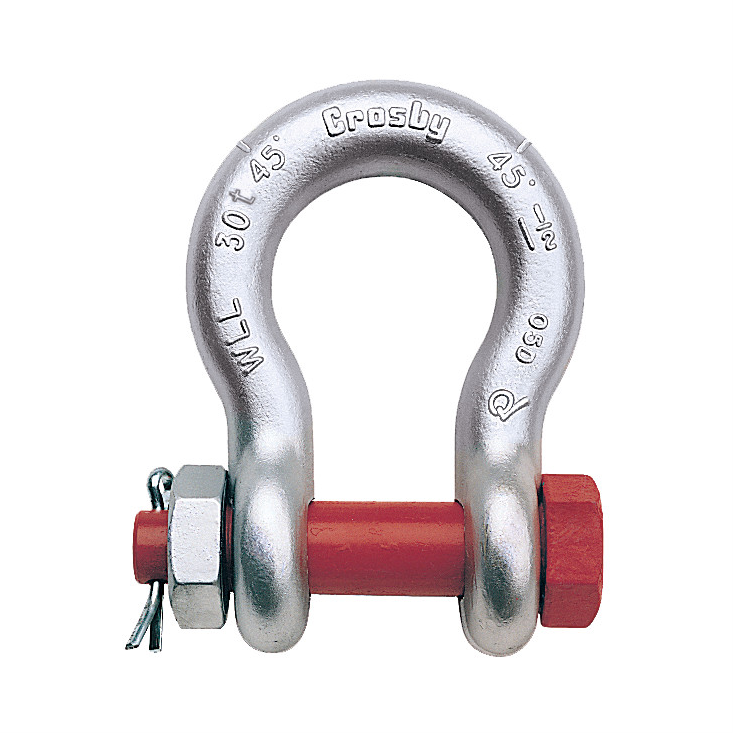

Bolt Type Shackles at Holloway Houston

At Holloway Houston, we take pride in offering a comprehensive range of bolt-type shackles for various heavy-duty lifting and rigging applications. With a selection of over 200 products, we offer shackles from top-tier manufacturers, including Green Pin, Crosby, and Yoke. Our collection features shackles in a wide range of sizes, materials, and configurations, catering to various industries, including construction, shipping, offshore operations, mining, and more. These shackles are designed to meet the demanding requirements of your projects and provide reliable connections for lifting, rigging, and securing loads.

Understanding Bolt Type Shackles

Bolt-type shackles are essential components used in rigging systems to connect equipment and secure loads. The design of a bolt-type shackle utilizes a bolt, nut, and cotter pin to secure the shackle pin in place, making it especially useful in applications where rotational forces could cause other types of shackles to open. This makes them ideal for environments where loads can shift or twist, such as in construction, offshore oil operations, or the handling of heavy machinery. The bolt, nut, and cotter pin arrangement makes sure the connection remains intact, even under challenging conditions.

These shackles come in two main types:

- Bow Shackles: Characterized by their rounded shape, bow shackles are designed to be used in multi-leg slings. Their shape allows for the connection of multiple slings to a single point, making them versatile and useful in a wide range of applications.

- Dee Shackles: These shackles have a straight body and are primarily used for direct attachments to chains, hooks, or other rigging components. They offer a more compact connection but are equally robust for heavy-duty tasks.

Bolt-type shackles serve as the link between chains, slings, hooks, and other rigging components, forming a vital part of many lifting systems. Their primary function is to securely fasten components together, ensuring that the load stays connected during lifting, lowering, or securing operations.

Key Features of Bolt Type Shackles

Materials

Bolt-type shackles are manufactured from various materials to meet the needs of different environments and conditions. The material chosen for a shackle plays a key role in determining its performance and suitability for applications.

- Carbon Steel: Carbon steel is commonly used for bolt-type shackles that will be subjected to general lifting tasks. It provides a balance between strength and cost-effectiveness, making it ideal for non-corrosive environments and tasks where weight is a concern.

- Stainless Steel: For environments that require corrosion resistance, such as marine or chemical applications, stainless steel is a popular choice. Stainless steel shackles can withstand exposure to saltwater, acids, and other harsh conditions, which would degrade other materials more quickly.

- Alloy Steel: When higher strength is required to support heavy loads or withstand shock loading, alloy steel shackles are utilized. Alloy steel is capable of handling extreme loads without compromising the integrity of the shackle, making it suitable for industries like mining, construction, and heavy lifting applications.

- Galvanized Steel: Galvanized steel shackles are created by coating carbon steel with zinc to protect it from rust and corrosion. These shackles are often used in outdoor environments, especially in areas prone to moisture or where exposure to weather conditions is a concern.

Sizes and Configurations

The bolt-type shackles in our range come in various sizes, ranging from 3/16" to 23.83" in diameter, with Working Load Limits (WLL) ranging from 0.33 tons (660 lbs) to 400 tons. This wide selection of sizes ensures that, regardless of the scale of the job you're undertaking, we have a shackle that meets your needs.

Here are some standard shackles sizes and their typical applications:

| Shackle Size | Typical WLL Range | Common Applications |

|---|---|---|

| 3/8" | 1–3 tons | Light equipment, small rigging |

| 1/2" | 2–6.5 tons | Construction, towing |

| 1" | 6.5–20 tons | Offshore rigging, industrial lifting |

| 3" | 35–75 tons | Heavy machinery, shipbuilding |

These sizes are versatile and cover a range of industries, from lightweight tasks to heavy-duty lifting, ensuring that whatever the application, a suitable option is available.

Design Specifications

In addition to material and size, bolt-type shackles are available in various design specifications to meet the specific requirements of different lifting jobs.

- Pin Diameter: The pin diameter varies according to the shackle size, typically ranging from 0.38 inches to 8.5 inches. A thicker pin can provide additional strength for larger shackles, making it more suited to heavy lifting tasks.

- Throat Opening: The throat opening of a shackle is a crucial measurement, as it determines compatibility with various slings or hooks. The throat opening typically ranges from 0.38 inches to 8.5 inches.

- Bow Diameter: Bow shackles feature a wide bow design that allows for the connection of multiple slings. The wider the bow, the more slings can be connected to the shackle, which is particularly helpful in multi-leg sling systems.

Applications of Bolt-Type Shackles

Construction:

Bolt-type shackles are frequently used in the construction industry for lifting steel beams, concrete blocks, pipes, and heavy machinery. They are also used to secure cranes, hoists, and other heavy equipment during rigging. Their robust design makes them ideal for withstanding the stress of construction sites, where heavy lifting and movement are common.

Shipping & Marine:

In the shipping and marine industries, bolt-type shackles are crucial for mooring ships and securing cargo. They are used to create strong and reliable connections between ships and docks, as well as to secure containers, equipment, and materials on vessels during transport. These shackles are also widely used in offshore oil rig installations, where exposure to harsh environmental conditions requires a secure and sturdy connection.

Mining:

The mining industry relies on bolt-type shackles to handle heavy-duty tasks such as attaching drilling rigs, conveyors, and other mining equipment. Mining operations often involve extreme environments and heavy shock loading, making it necessary for rigging components, such as shackles, to withstand these conditions. Bolt-type shackles made of alloy steel are a go-to solution for these types of applications.

Agriculture:

In agricultural operations, bolt-type shackles are used to lift tractors, hay bales, and irrigation equipment. These shackles can be applied in various farming activities, from moving large machinery to handling other heavy agricultural loads. They are handy when working in outdoor environments where exposure to weather and moisture can be a concern.

Utilities:

The utilities industry utilizes bolt-type shackles for installing power poles, transformers, and other large pieces of equipment. Their reliable strength ensures that utility companies can carry out lifting tasks without compromising on safety or efficiency.

Safety and Inspection:

The proper use and maintenance of bolt-type shackles are essential to ensure safe lifting operations. Regular inspections and adherence to safety guidelines help prevent accidents and ensure that shackles perform as intended.

Key Safety Practices

- Check WLL: Before using a shackle, always check the Working Load Limit (WLL) to ensure that it is not being overloaded. Exceeding the Working Load Limit (WLL) can result in equipment failure and accidents.

- Inspect Regularly: Inspect shackles regularly for signs of wear, cracks, deformation, or corrosion. Shackles that are damaged or worn out should be removed from service immediately to avoid failure during lifting operations.

- Secure the Pin: The bolt and cotter pin must be tightly fastened to prevent them from loosening during use. If the pin becomes loose, the shackle could fail under load, leading to accidents.

- Avoid Sharp Edges: Use edge protectors when working with slings to avoid cutting or damaging the rigging material. Sharp edges can weaken the slings, potentially leading to failure under load.

Following industry standards, such as OSHA and ASME B30.26, is critical to maintaining safe lifting operations and preventing accidents.

Related Products

At Holloway Houston, we offer a full range of rigging components to complement our bolt-type shackles. These include:

- Chains: Our Alloy Chain Slings are perfect for heavy-duty lifting tasks. With their robust construction, they work seamlessly with our shackles for reliable load securing.

- Hooks: Clevis Hooks are ideal for easy attachment of lifting slings and can be used in combination with shackles for added versatility.

- Wire Rope: Our Wire Rope Slings are designed for heavy lifting and work well with bolt-type shackles for applications that require strength and flexibility.

Why Choose Holloway Houston?

Choosing Holloway Houston means partnering with a trusted supplier that offers high-quality rigging products for all your lifting and securing needs. Here’s why our customers choose us:

- Top Brands: We stock shackles from reputable manufacturers such as Green Pin, Crosby, and Yoke, ensuring you receive top-quality products every time.

- Variety: Whether you need a small shackle for light lifting or a large one for heavy-duty tasks, we carry a range of sizes and Working Load Limits to suit every application.

- Expert Support: Our team is available to assist you in selecting the ideal shackles for your specific application. Whether you need technical advice or help with product selection, we're here to assist you every step of the way.

Get Started Today

Browse our complete range of bolt-type shackles online at Holloway Houston or reach out to us for personalized assistance. Our expert team is here to assist you in selecting the right product for your specific application. Don’t forget to download our Rigging Safety Guide for valuable tips on safe rigging practices.

Need a custom solution? We offer fabrication services for unique sizes or configurations that may be required for specialized jobs.