How to Use Chain Slings Safely and Effectively

How to Use Chain Slings Safely and Effectively

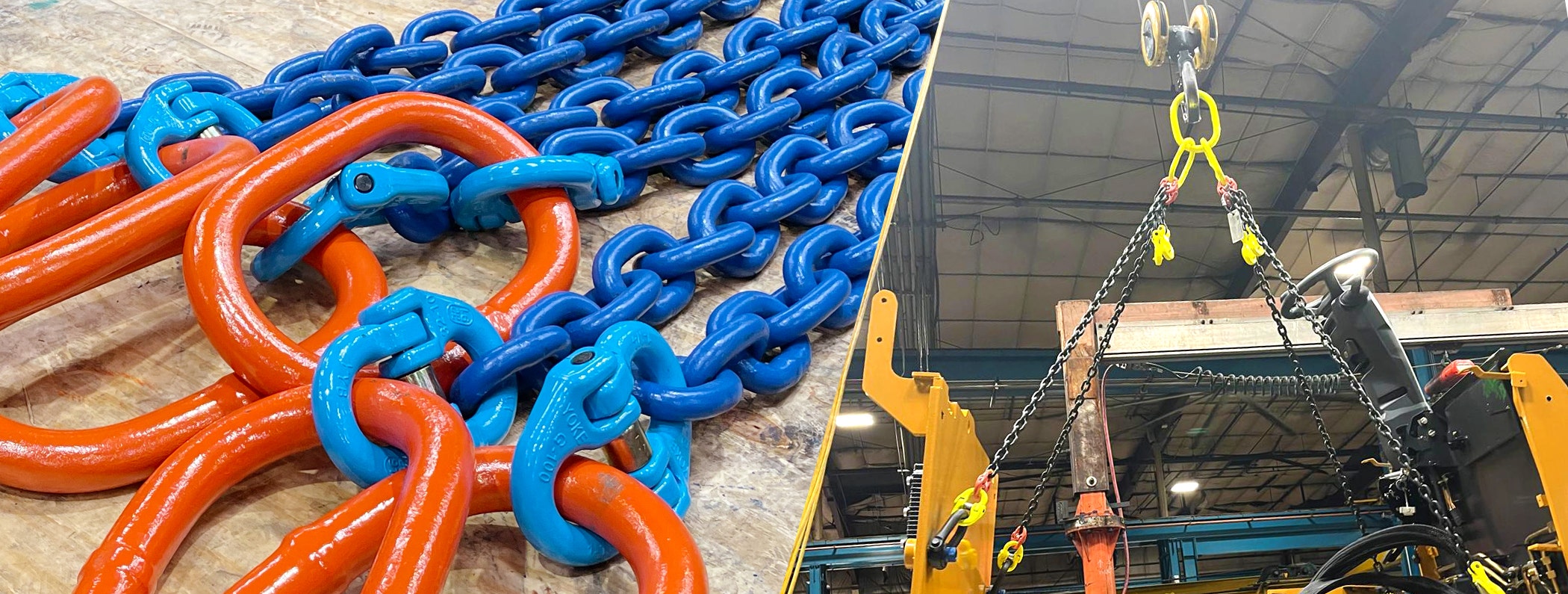

Chain slings are essential tools across various industries, from construction sites and manufacturing floors to the demanding environments of transportation and logging. Renowned for their strength, durability, and resilience to heat, they provide a reliable solution for lifting and moving heavy loads. However, the correct application of chain slings is essential for safety and operational efficiency. This guide provides an overview of chain sling usage, with a focus on Grade 100 chain slings, a popular choice due to their impressive strength and lighter weight.

Types of Chain Slings

Single-Leg: Commonly used for vertical lifts and choker hitches, where the sling wraps around the load.

- Use Cases: Handling cylindrical items like pipes or logs, securing loads, and towing.

- Advantages: Simple design, easy to inspect.

- Limitations: Lower weight capacity compared to multi-leg slings.

Double-Leg: Offers versatility for vertical, choker, and basket hitches.

- Use Cases: Lifting heavy machinery, steel plates, and containers.

- Advantages: Higher weight capacity and improved load control compared to single-leg slings.

- Limitations: Requires precise rigging for balanced loading.

Triple/Quad-Leg: Used for complex lifts requiring multiple attachment points.

- Use Cases: Moving large or irregularly shaped loads and securing items that may shift.

- Advantages: Provides stability and control for uneven loads.

- Limitations: Involves more complex rigging, requiring detailed planning and inspection.

Materials

Grade 100 Alloy Steel: This high-strength material is widely used in chain slings, valued for its durability and resistance to wear, making it suitable for challenging applications.

Essential Chain Sling Fittings

While the chain provides lifting strength, the fittings connect it to the equipment and load. Selecting the right fittings and keeping them in good condition is essential to safe and effective lifting operations.

Hooks

- Grab Hooks: Commonly used in chain slings, grab hooks have a wide throat opening that accommodates a range of lifting points.

- Self-Locking Hooks: Designed with a latch to prevent accidental detachment, these hooks are suitable for lifts where the load may shift or vibrate.

- Clevis Hooks: Built for use with clevis attachments, these hooks offer a secure and rigid connection.

- Slip Hooks: Known for quick and easy attachment and detachment, slip hooks are ideal for tasks requiring frequent connections.

Master Links

- Oblong Master Links: Used in multi-leg slings to connect all legs to one lifting point. The oblong shape helps balance the load across the sling legs.

- Weldless Master Links: Forged from a single steel piece, these links provide high strength and durability.

Connecting Links

- Connecting links join chain sections or attach fittings to the chain, providing a secure connection in various lifting setups.

Shackles

- Screw Pin Shackles: Easily adjustable and commonly used for temporary connections.

- Bolt-Type Shackles: Built for heavy-duty applications, these shackles offer high strength for secure connections.

Choosing the Right Fittings

Selecting fittings that are compatible with the grade and size of your chain sling is essential for safe and effective lifting. Choosing quality fittings from trusted manufacturers like Crosby, Gunnebo Johnson, and Pewag further supports safety and reliability in lifting operations.

Leading Brands

Holloway partners with top brands to provide quality and reliability in chain sling components:

- Crosby: A well-regarded brand for dependable hooks, shackles, and master links, providing secure connections.

- Gunnebo: Known for durable and innovative lifting solutions that support safety and efficient operation.

- Pewag: A global leader in lifting technology, offering chain sling components that meet strict quality standards.

- Yoke Industrial: Specializes in high capacity lifting equipment, including master links and shackles for handling heavy loads.

- Carcano (Cartec): Provides a full range of chain sling components, such as hooks and connecting links, providing compatibility and reliable performance.

Chain Types

- Peerless: Offers high-quality chain with exceptional strength and reliability, ideal as a foundation for chain slings.

- Pewag: Provides specialized chains tailored for different applications, enhancing performance and safety.

- McKinnon: Known for producing durable chain products that contribute to the longevity and reliability of chain slings.

Safe Lifting Techniques with Chain Slings

Understanding Working Load Limits (WLL)

The Working Load Limit (WLL) represents the maximum weight a chain sling can safely lift. Exceeding this limit risks accidents and equipment damage. Key factors that influence WLL include:

- Size and Grade of Chain: Thicker chains and higher grades support greater weights, allowing them to handle heavier loads.

- Number of Legs: Multi-leg slings distribute the load across multiple legs, resulting in higher WLLs compared to single-leg slings.

- Angle of Lift: As the angle between the sling legs and the vertical line narrows, WLL decreases because the tension on each leg increases. Always refer to a WLL chart for adjusted limits at different angles.

- Wear and Tear: Damaged or worn chains reduce the WLL, affecting lifting capacity and safety.

Hitching Methods

Choosing the correct hitching method is essential for safe and efficient lifting. Here are common hitching methods:

- Vertical Hitch: Sling legs hang vertically from the lifting point, allowing the sling to operate at its full WLL.

- Choker Hitch: The sling wraps around the load and is secured or "choked" on the hook. This configuration reduces the WLL by around 25% due to increased chain stress.

- Basket Hitch: The sling cradles the load with both legs passing through the master link, providing stability and making it ideal for lifting objects with a broad base.

Pre-Use Inspection

What is ASME B30.26?

ASME B30.26 is a standard established by the American Society of Mechanical Engineers (ASME) that outlines safety guidelines for "below-the-hook" lifting devices, including chain slings, wire rope slings, and synthetic web slings. It covers the construction, installation, operation, inspection, and maintenance of these devices to support safe lifting practices.

Inspection Checklist (based on ASME B30.26):

- Chain:

- Wear and Elongation: Use a caliper to measure chain links for any elongation beyond the maximum limit (typically 3% in a single link). Inspect for wear patterns, especially where the chain contacts hooks or master links, and check for reduced link diameter that may indicate weakening.

- Damage: Inspect each link for cracks, gouges, bends, or twists, paying close attention to areas typically hidden during use.

- Heat Damage: Check for any discoloration (such as blue or black marks), which can indicate heat exposure that weakens the chain.

- Hooks:

- General Condition: Examine the hook body for any cracks, deformation, or other damage, especially in the saddle area and tip.

- Latch and Safety Catch: Confirm the Latch closes properly and the safety catch functions to prevent the load from accidentally disengaging.

- Throat Opening: Inspect for wear or distortion in the throat opening, as this can affect the hook’s strength and secure load holding.

- Master Links and Connecting Links:

- Deformation: Check that links are free from bending, twisting, or any other deformation, which may reduce load-bearing capacity.

- Wear: Look for signs of abrasion or gouging at points where the links make contact with the chain.

Choosing the Right Chain Sling

Selecting the appropriate chain sling involves evaluating several key factors:

- Load Weight: Confirm the weight of the load to match the sling’s capacity matches the requirement.

- Load Type: Consider the load's shape, center of gravity, and stability to select a sling configuration that offers sufficient support.

- Lifting Environment: Assess temperature, chemicals, and potential hazards in the area to choose a sling with the appropriate material and construction.

- Reach: Measure the length required to safely connect the lifting point to the load.

Careful consideration of these factors helps in choosing the right chain sling for the task, improving safety and operational efficiency.

Chain Sling Care and Maintenance

Proper care and maintenance help extend the lifespan of chain slings and keep them safe for continued use:

- Storage: Store chain slings in a clean, dry area, away from moisture and chemicals that may cause corrosion. Hang slings on racks or keep them in coils to prevent kinking and damage.

- Cleaning: Clean chain slings regularly to remove dirt, grease, and debris from usage. Use mild detergent and water, avoiding harsh chemicals that could harm the chain.

- Lubrication: Periodically lubricate chain slings to minimize friction and wear between links. Use a manufacturer-recommended lubricant to maintain compatibility and performance.

- Inspection Frequency:Inspect chain slings before each use and conduct more detailed inspections at regular intervals based on the sling’s frequency of use.