Hammerhead Slings by Holloway

Holloway introduces our Hammerhead Endless Slings. They are produced using the highest strength synthetic rope, Plasma.

Plasma 12-Strand is manufactured from High Modulus PolyEthylene (HMPE) that is enhanced by Cortland’s patented recrystallization process. Each sling is then covered with a braided Polyester cover utilizing our priority braiding machine. Each sling is then coated with an abrasion resistant FiberLock coating. The lower load slings are color coded based on vertical working loads. Custom colors are available. Each Sling is proof loaded with certification. Custom covering utilizing fibers such as Spectra, Technora, Kevlar, etc. is available.

While utilizing these slings, your minimum D/d is 2:1. However, it is suggested to use the sling at a 3:1 D/d to increase the longevity of the sling’s lifespan.

Sling working loads are based on a 5:1 factor of safety.

- Light Weight

- Low Stretch

- Repairable

- Easy Handling

- Inspection and recertificationa

- High Strength

Minimum Break Load (MBL) in pounds or tonnes and is determined using spliced test samples in accordance with Cordage Institute 1500-02 - Test Method for Fiber Ropes.

Minimum Sling Length on Eye & Eye fabricated Cortland slings assumes.

- A compressed minimum eye splice of 6.75 times the rope diameter in inches.

- A clear span area between splices of 10 times Cortland rope circumference in feet

The recommended Design Factor (DF) of 5:1 on this chart is based on several existing lifting sling standards including ASME B30.9. This design factor takes into account various factors including the use of UHMWPE (Ultra High Molecular Weight Polyethylene) fiber which is extremely durable and resistant to repeated high loads. Plasma® rope slings have and can be used with different DF ratios: however, this is a decision which must be made by a qualified person or designer of the lift in conjunction with the rope manufacturer.

Cortland, at this time, does not recommend the use of Plasma rope slings in a choker hitch at a lifting angle of less than 120°. Testing on rated values is not complete and available at this time.

Bending Guidance

In theory, a sling used in a basket configuration could have twice the working load as a sling in a vertical configuration because two ropes are now holding the load instead of one. However, because of bending reductions this theory is incorrect. Users must reduce that factor-of-two by an efficiency factor (i.e., a bending reduction factor).

The more tight a bend is, the more the bending efficiency reduces. If you have a gentle bend, the D:d ratio might be very high. But as the D:d ratio goes down, the bending reduction increases. Example: a 5:1 D:d ratio provides only 80% efficiency.

Reduced Basket Capacity Calculation

C = B x e

C = Reduced Basket Capacity due to bending efficiency reduction

B = Rated Basket Capacity with consideration of horizontal sling fleet angle

e = Bending efficiency percentage Bending Guidanc

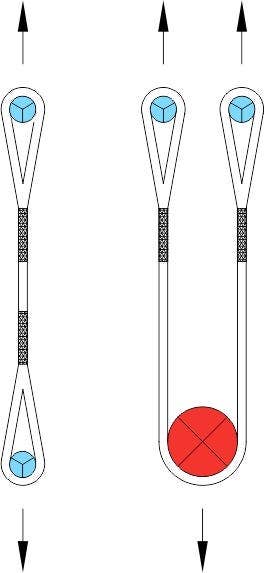

Represents a contact surface that is equal to or greater than the rope diameter.

Represents a contact surface that is equal to or greater than the rope diameter.

Represents a contact surface with a D:d ratio of one or greater. Refer to the Efficiency Table for deductions as needed.

Represents a contact surface with a D:d ratio of one or greater. Refer to the Efficiency Table for deductions as needed.

| Efficiency Table | |

|---|---|

| D:d Ratio | eff % (e) |

| 25:1 | 100.0% |

| 8:1 | 82.5% |

| 5:1 | 80.0% |

| 3:1 | 75.0% |

| 2:1 | 72.5% |

| 1:1 | 65.0% |

Hammerhead Slings: The Strongest, Lightweight, and Most Versatile Slings on the Market

Rated Capacities in Pounds

| Part No. | Vertical* | Choker | Vertical Basket** | Min Length | Rope Dia. | Approx. Sling Dia | Approx wgt. per linear ft. of sling |

|---|---|---|---|---|---|---|---|

| HH-9-EPC | 5,700 | 4,600 | 11,500 | 2′ | 3/8” | 1/2” | 0.09 |

| HH-11-EPC | 6,900 | 5,500 | 13,800 | 2′ | 7/16” | 9/16” | 0.11 |

| HH-12-EPC | 10,300 | 8,200 | 20,600 | 2′ | 1/2” | 11/16” | 0.16 |

| HH-16-EPC | 16,900 | 13,500 | 33,900 | 2′ | 5/8” | 7/8” | 0.27 |

| HH-18-EPC | 22,600 | 18,000 | 45,200 | 2′ | 3/4” | 1” | 0.33 |

| HH-22-EPC | 30,500 | 24,400 | 61,000 | 2.5′ | 7/8” | 1-3/16” | 0.49 |

| HH-24-EPC | 36,300 | 29,000 | 72,600 | 2.5′ | 1” | 1-3/8” | 0.59 |

| HH-28-EPC | 48,500 | 38,800 | 97,000 | 3′ | 1-1/8” | 1-1/2” | 0.80 |

| HH-30-EPC | 54,400 | 43,500 | 108,800 | 3′ | 1-1/4” | 1-5/8” | 0.91 |

| HH-36-EPC | 72,000 | 58,000 | 145,000 | 3.5′ | 1-1/2” | 2” | 1.29 |

| HH-40-EPC | 96,000 | 76,000 | 192,000 | 3.5′ | 1-5/8” | 2-3/16” | 1.65 |

| HH-44-EPC | 103,000 | 82,000 | 207,000 | 4′ | 1-3/4” | 2-3/8” | 1.95 |

| HH-48-EPC | 117,000 | 93,000 | 234,000 | 4′ | 2” | 2-5/8” | 2.28 |

| HH-52-EPC | 141,000 | 112,000 | 282,000 | 4.5′ | 2-1/8” | 2-7/8” | 2.73 |

| HH-56-EPC | 158,000 | 126,000 | 317,000 | 4.5′ | 2-1/4” | 3” | 3.05 |

| HH-60-EPC | 174,000 | 139,000 | 349,000 | 5′ | 2-1/2” | 3-3/8” | 3.70 |

| HH-64-EPC | 196,000 | 157,00 | 393,000 | 5′ | 2-5/8” | 3-1/2” | 4.18 |

| HH-68-EPC | 217,000 | 174,000 | 435,000 | 6′ | 2-3/4” | 3-5/8” | 4.68 |

| HH-72-EPC | 257,000 | 205,000 | 514,000 | 6.5′ | 3” | 4” | 5.35 |

| HH-76-EPC | 280,000 | 224,000 | 561,000 | 6.5′ | 3-1/8” | 4-1/8” | 5.88 |

| HH-80-EPC | 310,000 | 248.000 | 620,000 | 6.5′ | 3-1/4” | 4-3/8” | 6.53 |

| HH-84-EPC | 365,000 | 292,000 | 731,000 | 7.5′ | 3-1/2” | 4-5/8” | 7.45 |

| HH-88-EPC | 412,000 | 330,000 | 825,000 | 7.5′ | 3-5/8” | 4-7/8” | 8.10 |

| HH-96-EPC | 501,000 | 401,000 | 1,003,000 | 8.5′ | 4” | 5-3/8” | 9.85 |

| HHI PartNumber | Rope DiameterInches | Vertical WLLMetric Tons | G-2160 ShackleWLL (mt) | Wide BodyWidth (ins.) | D/d |

|---|---|---|---|---|---|

| HH-9-EPC | 0.3375 | 2.1 | 7 | 1.6 | 4.27 |

| HH-11-EPC | 0.4375 | 3.4 | 7 | 1.6 | 3.66 |

| HH-12-EPC | 0.5 | 4.69 | 7 | 1.6 | 3.20 |

| HH-16-EPC | 0.625 | 7.7 | 12.5 | 2.13 | 3.41 |

| HH-18-EPC | 0.75 | 10.26 | 12.5 | 2.13 | 2.84 |

| HH-22-EPC | 0.875 | 13.86 | 18 | 2.5 | 2.86 |

| HH-24-EPC | 1 | 16.47 | 18 | 2.5 | 2.50 |

| HH-28-EPC | 1.125 | 22.01 | 30 | 3.13 | 2.78 |

| HH-30-EPC | 1.25 | 24.71 | 30 | 3.13 | 2.50 |

| HH-36-EPC | 1.5 | 33.09 | 40 | 3.75 | 2.50 |

| HH-40-EPC | 1.625 | 43.57 | 55 | 4.5 | 2.77 |

| HH-44-EPC | 1.75 | 47.01 | 55 | 4.5 | 2.57 |

| HH-48-EPC | 2 | 53.15 | 55 | 4.5 | 2.25 |

| HH-52-EPC | 2.125 | 64.08 | 75 | 4.75 | 2.24 |

| HH-56-EPC | 2.25 | 72.02 | 75 | 4.75 | 2.11 |

| HH-60-EPC | 2.5 | 79.36 | 125 | 5.91 | 2.36 |

| HH-64-EPC | 2.625 | 89.24 | 125 | 5.91 | 2.25 |

| HH-72-EPC | 3 | 116.79 | 125 | 5.91 | 1.97 |

| HH-80-EPC | 3.25 | 140.74 | 200 | 8.63 | 2.66 |

| HH-88-EPC | 3.625 | 187.16 | 200 | 8.63 | 2.38 |

| HH-96-EPC | 4 | 227.59 | 300 | 10.38 | 2.60 |