The Best Industrial Lifting Equipment of 2020

Quality is the most important factor when purchasing industrial lifting accessories in rigging equipment. While many get caught up in sticking to a budget, going with lower-end brands or cheaper options can end up actually costing more in the long run. This equipment wears down at a faster rate and needs more frequent replacements or repairs.

Better equipment provides better results – not to mention a safer workplace. Unfortunately, injuries are quite common in industrial workplaces. But many serious injuries (and even deaths) could be prevented by using better equipment with higher safety ratings and superior durability.

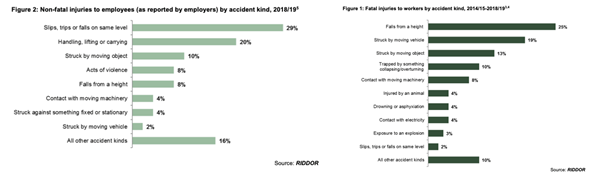

According to the latest report on workplace accidents from the Health and Safety Executive Office, 13% of fatal injuries and 20% of non-fatal injuries were caused by strikes from moving or falling objects. By using safe, top-quality lifting equipment parts like lifting hooks, clamps, and shackles from highly-rated manufacturers, these dangerous situations could be avoided.

If you are trying to find the best lifting accessories in rigging, look no further.

Here are some of the best industrial lifting supplies you need to create a better and safer working environment for your next project.

1. Heavy Duty Industrial Synthetic Slings

Generally, wire rope and chain slings are considered to be the best choice for heavy-duty or heavy lifting applications. While chain slings and wire ropes do have a high weight capacity, they have some disadvantages.

For instance, wire ropes can easily start to wear down and are non-repairable, while chain slings are extremely heavy and are not adjustable for varying lifting applications.

While chain slings and wire ropes certainly are the right choice for certain projects, industrial synthetic rigging slings are a smart alternative that offers numerous benefits.

Synthetic slings, on the other hand, are quite versatile and can be made of polyester, nylon, and other high-performance webbing materials. They also come in varying styles, including:

- Flat web slings

- Round slings

- Eye and Eye

- Endless Round Sling

- Choker Fittings

- Wide Lift Web

Synthetic slings are extremely flexible and they prevent items from being scratched or damaged during movement, making them an ideal choice for multiple types of lifting applications. Some of the highest-rated synthetic slings can even lift up to 600 Tons with a 5:1 ratio for superior performance – even in extreme conditions.

2. Bishops Specialized Wire Ropes

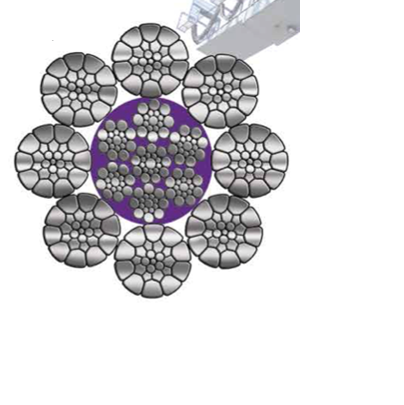

Wire ropes are the preferred choice for mining equipment, crane ropes, and heavy-duty lifting applications where durability and strength are paramount. However, as mentioned before, wire ropes do wear down over time – particularly if they are exposed to extreme temperatures, experience corrosion, or are crushed under pressure.

However, Bishops have created specialized wire ropes designed to promote a longer-lasting service life and improve fatigue resistance.

For instance, the BXL IWRC rope is filled with plastic to fill in the gaps between the core and the strands of wires. This helps to protect it from being easily crushed, while also increasing resistance to fatigue and abrasion.

Bishop also offers compacted strands, which feature multiple sized strands woven together to create a much stronger rope. This helps to extend the life of the rope and give it a higher breaking strength than traditional wire ropes.

3. Crosby Alloy Chains

If you are looking for a long-lasting and extremely heavy-duty lifting accessory in rigging, an alloy chain is your best option. Alloy chains are made of a combination of two or more types of metal (typically steel) to maximize strength and resilience.

Crosby rigging alloy chains are one of the top-line brands for a good reason. Their specialized heat treatment processes and designs ensure long-lasting chains that can be used for multiple applications, including towing, logging, binding, and overhead lifting.

The Grade 80 Alloy Chain from Crosby is one of the best rated for overhead lifting as it is made of the only grade approved by OSHA for this type of application. It is made from heat-treated steel, which helps to protect it from scratches, corrosion, and other extreme wear. It is considered to be one of the most ideal choices for lifting slings and towing chains.

The newest and strongest chain from Crosby is the Grade 100 Alloy Chain, which has a 25% higher working load limit than the Grade 80. It has also been tested to be stronger than lower grade chains in ambient temperatures, making it a superior choice for more extreme weather environments.

4. Tempered and Quenched End Fittings

End fittings are used to clamp the ends of synthetic or wire ropes which have been cut to fit a specific length for individual projects. Should these endings crack, corrode, or become distorted, it could expose the ends of these ropes, causing them to detach or unravel. Therefore, having a strong, long-lasting end fitting on ropes for lifting equipment is crucial.

Wire rope end fittings may also be used for various types of attachments. There are numerous types of end fittings, such as:

- Splice and Thimble

- Sockets

- Buttons

- Threaded Studs

- Wire Rope Clips

Each of these types has its own benefits and disadvantages, and some are more efficient and effective than others – considering their higher breaking strength.

But in addition to choosing the style of end fitting that is best for your application, you must also consider the material. Choosing an ending that is quenched and tempered can help to increase the fitting’s strength, durability, and longevity.

When a metal is quenched and tempered, the metal (typically a steel or iron-based alloy) is heated and then rapidly cooled, which allows the metals to settle into place quite quickly. It is commonly cooled with water, oil, forced air, or gases like nitrogen to decrease the temperature at a very fast rate.

This makes for an exceptionally strong end fitting, which can withstand lots of wear and tear and is suitable for more heavy-duty applications.

5. Innovative Load Shackle Rigging Attachments

Shackle rigging attachments are utilized for load attachment and are commonly used in oil rigging, lifting equipment, ships, and docks, as well as permanent securement. They are easily identified by their horseshoe shape (called the bow) with a removable pin that runs through the bottom. Many shackles also include an additional lock to hold the pin in place.

There are four main types of shackles:

- Anchor

- Chain

- Screw pin

- Bolt

While all of these shackles are essentially the same shape, the difference is in the way that the pin is secured within the ears of the shackle. Screw pins are screwed in and are ideal for equipment that is consistently attached and detached. Bolt type shackles use a bolt to secure the pin, making it best for long-term securement.

There are some special types of shackles, too – which are common in rigging equipment. This includes wide body shackles, long reach shackles, or sheet piles.

While this piece seems to be fairly basic and simple on the surface, opting for an innovative design can make your load shackle far more durable and safer. Scotland’s load shackles are specifically designed for overhead liftings applications with limited headroom and can even be made from full stainless steel for weight loads of up to 120 Tons.

Scotland also offers zone 1 and zone 2 hazardous area load shackles. These can be used in conjunction with wireless monitoring technology that uses sensors to send alerts of damage or slipping.

Conclusion

The success and safety of any project are dependent on the types of materials and equipment used on the job site. Opting for lower quality products to save a few dollars could end up not only costing you more – but it could put your crew in danger.

If you have any questions regarding these products or other equipment on our website, please reach out to our knowledgeable staff at Holloway Houston Inc. Our team will help to point you in the right direction to choose all of the rigging and lifting equipment that you will need for the next project.